SIPS

SIPs Outperform Stick & Batt (Oak Ridge National Labs R-Value Test)

When someone says "R-value", what they're really talking about is resistance to heat flow in a given medium, such as fiberglass insulation. The higher the number, the greater the resistance. So when a builder is asked "What's the R-value of this wall?", the natural inclination is to think of the material that most commonly specifies its rating. More often than not, it's the insulation, and the response is something along the lines of "Oh, that wall has an R-value of 24" - fairly impressive, but also strikingly inaccurate.

It's not that the builder is intentionally misleading his client or associate, but that he's just following common practice. In reality, this reasoning doesn't take into account all the other components that go into making a wall: wood or steel studs every 16" or 24", bracing, nails or screws, wiring and switch boxes - any number of things that are not insulation, and in all likelihood, have R-values that fall well short of the stated R-24.

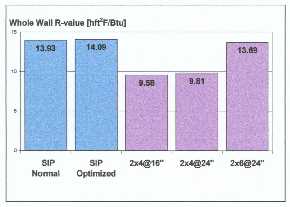

A new study by the Oak Ridge National Labs (ORNL) proves that a 4-inch SIP wall outperforms 2"x4" stick and batt construction, and even edges out 2"x6" construction in terms of thermal performance. Because SIPs are the structural elements, there are no studs or braces to cause breaks in the insulative action. The end result is a more comfortable, energy efficient structure that performs up to spec in real-world conditions. Unlike stick and batt construction, which can be subject to poorly installed - even missing - insulation, the nature of SIPs is such that the structural and insulative elements are joined as one. There are no hidden gaps, because a solid layer of foam insulation is integral to panel construction.

By contrast, state-of-the-art technical analysis of whole wall performance indicates that the losses in a stud wall are much greater than you might think: on average, the other standard components in stick and batt construction can reduce R-values in as much as 30% of the wall area. Fortunately, that's not the case with structural insulated panels. The ORNL study found that SIPs perform at approximately 97% of their stated R-value overall, losing only 3% to nail holes, seams, splines, and the like. Wiring chases are precut or preformed into the foam core, providing a continuous layer of insulation keeping the elements at bay and the interior free of drafts and cold spots.

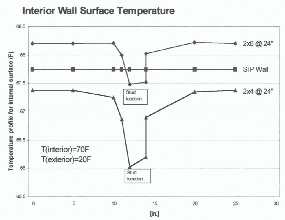

A SIP wall also outperforms stick and batt when it comes to maintaining consistent interior temperatures, and that translates to improved occupant comfort. As shown in the graph below, the interior surface temperature of frame construction drops precipitously at every stud, while the SIP wall remains consistent across its entire surface. No temperature dips mean improved occupant comfort, regardless of where you are in the room. That's a big part of what people are talking about when they say they can immediately "feel the difference" in a SIP-built residential or commercial space. With SIPs, thermal efficiency and comfort are built in at the factory, and now the lab results prove it.

Interior surface temperature comparisons indicating constant temperature for SIP wall and reductions in temperature at stud locations for 2"x 4' and 2" x 6" wood frame walls (ORNL).